Processes

10+ Years of Experience in Manufacturing

Engineering

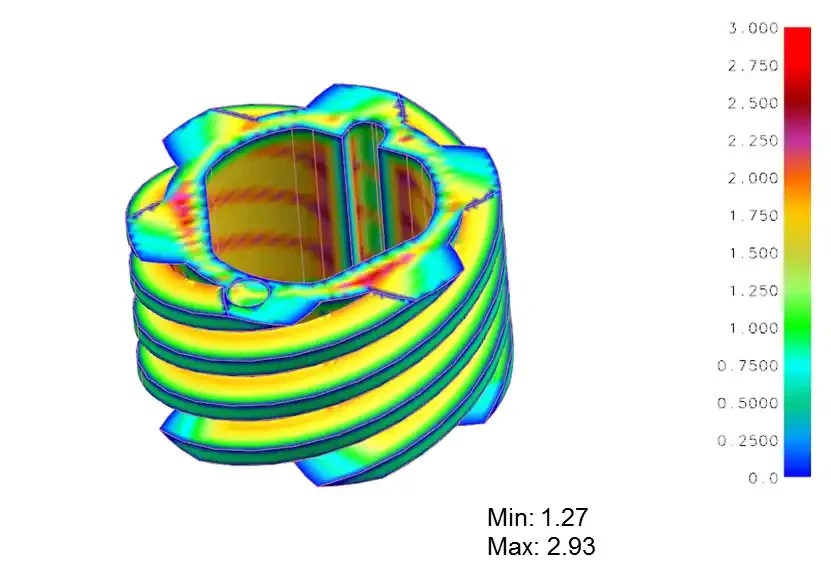

Analysis

Design for Manufacturability

Thorough review of designs before production ensures parts are ready for injection molding.

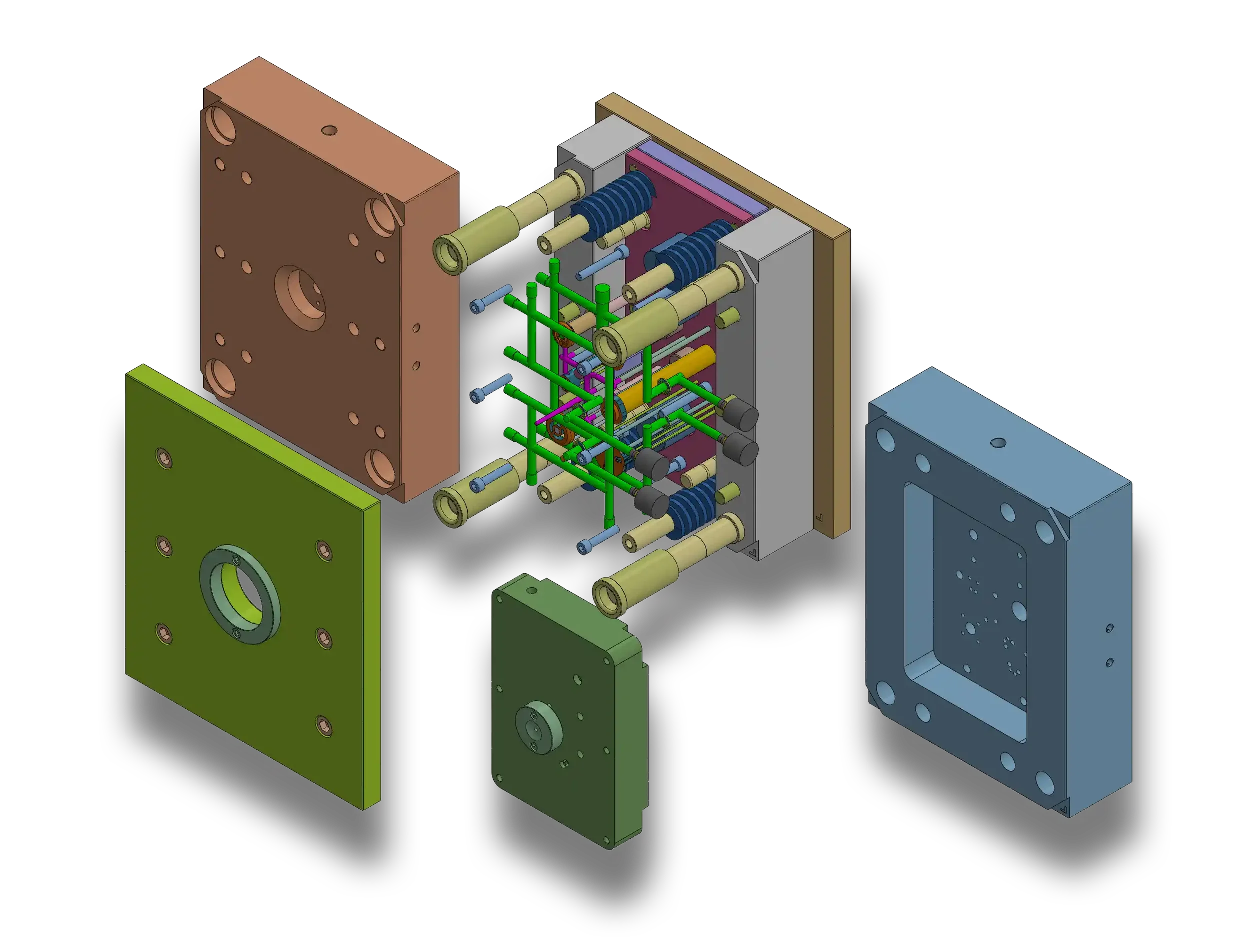

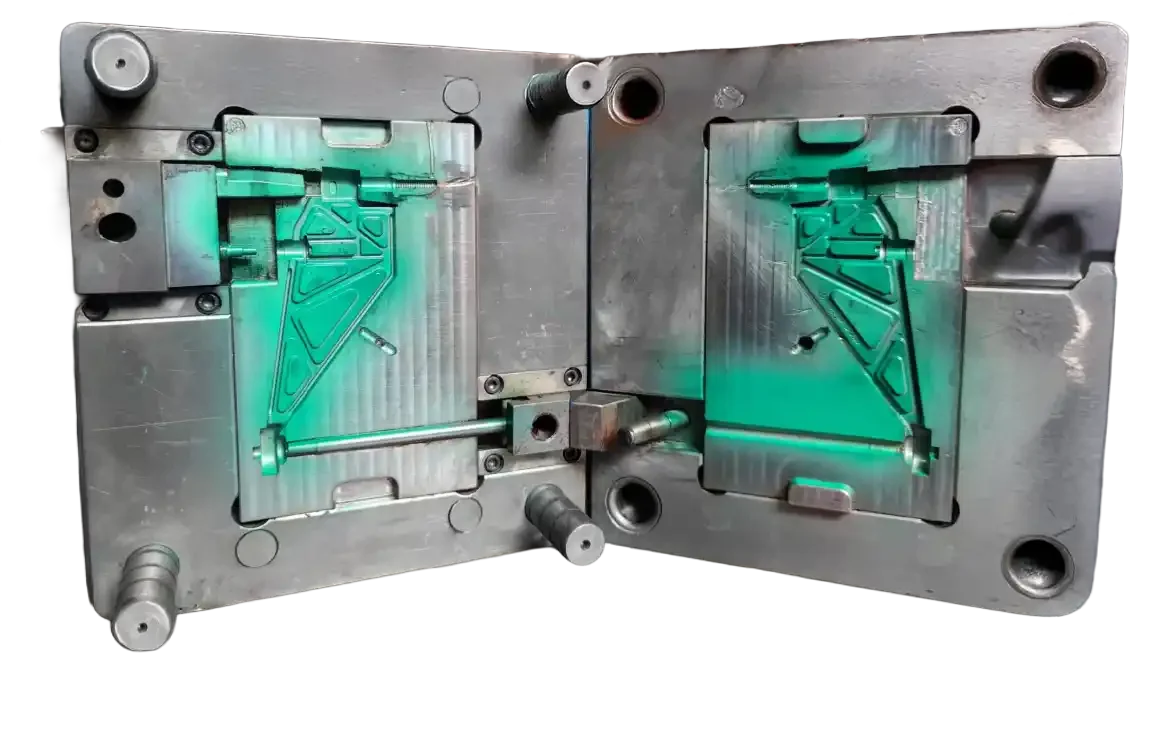

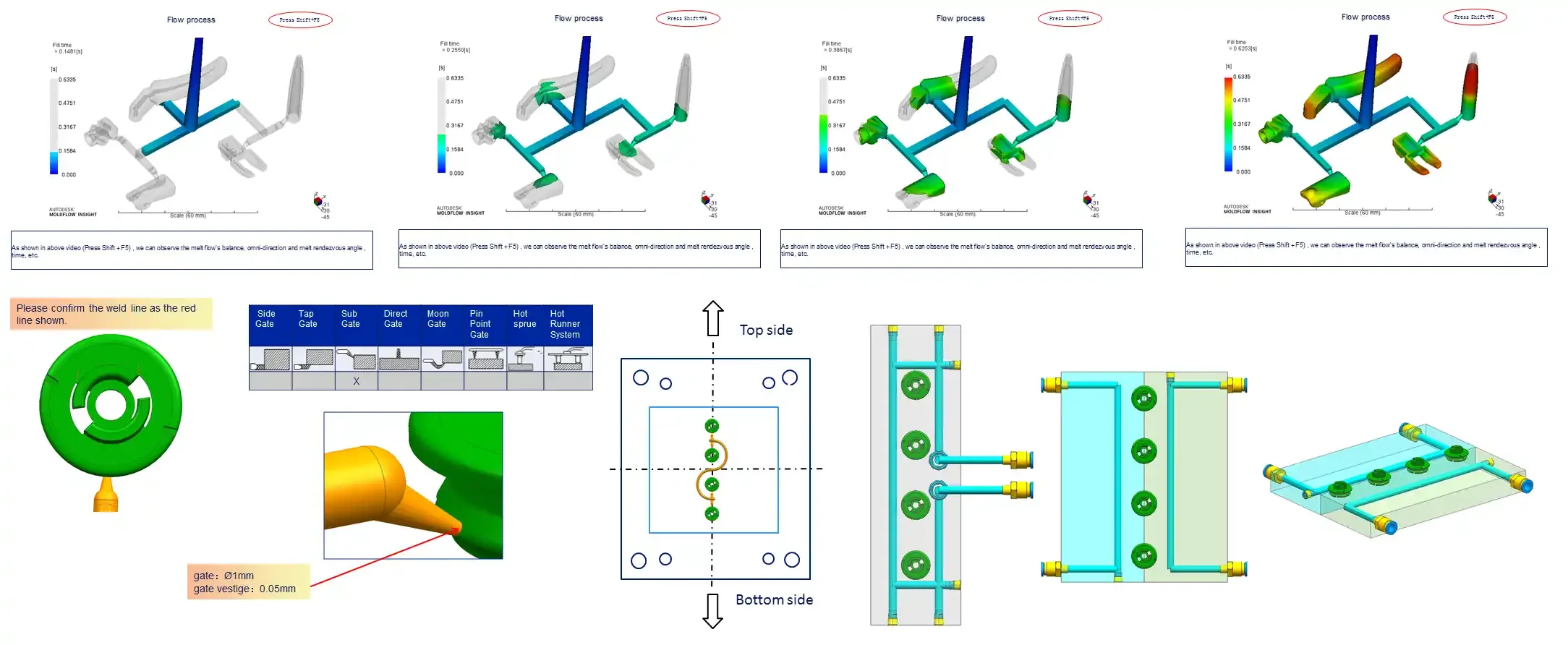

Efficient Mold Design

An efficient mold design reduces the complexity, and in turn lowers both lead time and cost.

Project

Management

Short Development Time

Launching in time can be the difference between market viability and market failure, and quick time to value is key.

Rapid Response

Projects can require informed decisions and quick changes to stay agile, making rapid responses critical to project timeline.

Low Cost Molds

Low cost is the focus of each project, as it can make or break the resource allocations for other key areas of a product.

Production

Management

Quality Control

Customers expect high quality parts to come from your project, and ensuring quality is essential for your reputation.

Support and Maintenance

Molds require maintenance to keep their performance at optimal levels and keep ongoing cost low.

Low Cost Molds

Why It Matters

Low-volume molds typically have higher per-part costs than high-volume molds. 365 Molding is specialized in ensuring these costs are minimized by optimizing mold design and understanding common challenges in keeping production costs controlled.

How We Succeed

Review the part design before tooling begins to avoid unnecessary modications.

Offer modular mold designs that reduce tooling complexity and cost, especially for customers who need multiple parts.

Suggest cost-saving options (e.g., optimizing part design, using cost-effective materials) to help control the overall investment.

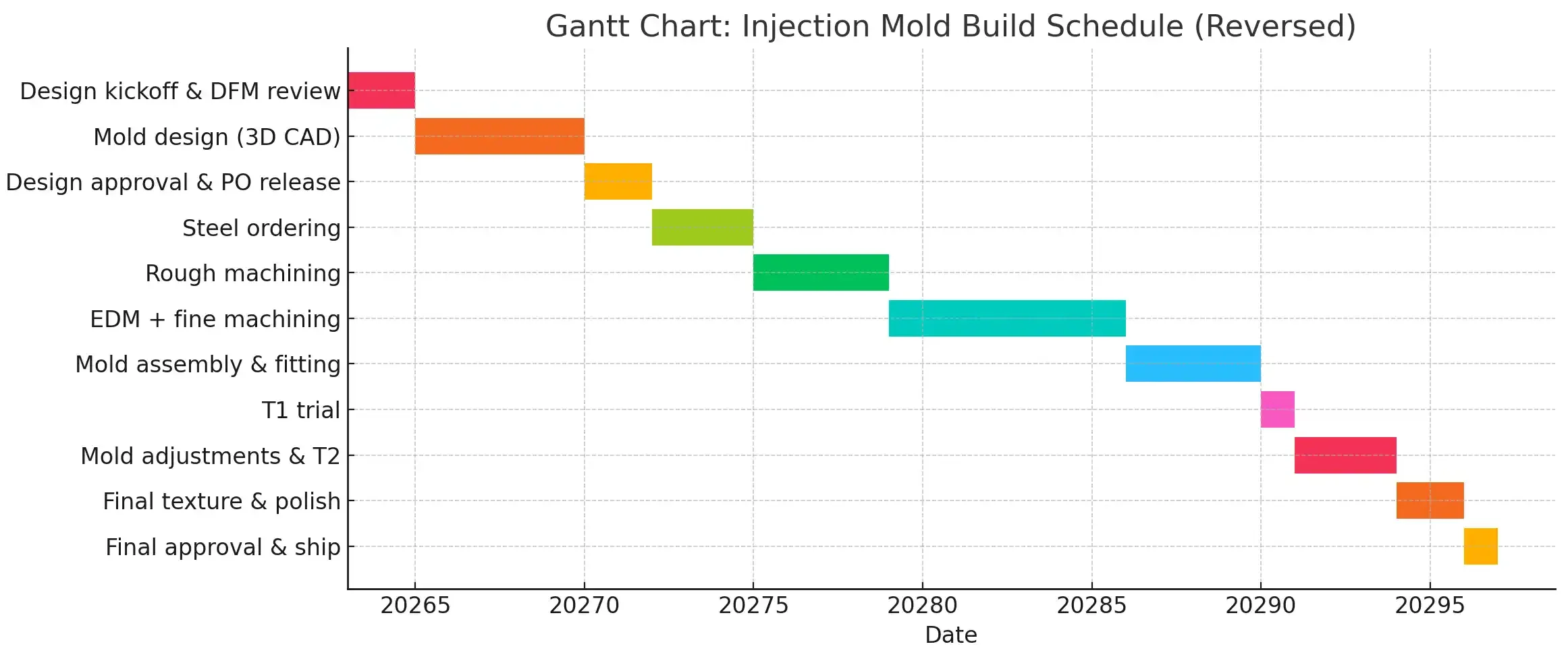

Short Development Time

Why It Matters

In low-volume production, project owners need parts quickly, especially for prototype testing, marketing evaluation, or new product launches. The viability of a product may still be in the early stages and short lead time is critical to staying competitive.

How We Succeed

Use rapid prototyping (3D printing or CNC machining) to shorten development time for concept models/prototypes.

Streamline parallel processes, like designing and sourcing materials simultaneously, to reduce total project time.

Optimize and expedite the process from the start to maintain efficiency in mold fabrication while ensuring quality.

Efficient Mold Designs

Why It Matters

Efficient mold designs reduce production costs and lead times while offering flexibility for small or multiple part variations. This is key for low-volume production, where project owners need flexibility without increasing costs.

How We Succeed

Family Molds: Use of family tooling to mold multiple parts in one mold, often simultaneously, reduces the need for multiple molds and lowering the overall cost.

Interchangeable Inserts: Design molds with interchangeable inserts quickly adapt to different part derivatives without creating an entirely new mold.

Modular Mold Frames: Allow for quick mold changes with universal frames, which minimizes tooling and setup costs.

Rapid Response to Inquiries

Why It Matters

Low-volume injection molding projects often require fast decisions and frequent changes. A rapid, responsive communication strategy is required to ensure that projects stay on track and on schedule without leaving the project owner in the dark.

How We Succeed

Respond quickly to customer inquiries, providing clear answers within one business day.

Offer weekly progress updates to keep project owners informed, from mold design through production, with full explanation and engagement throughout the process.

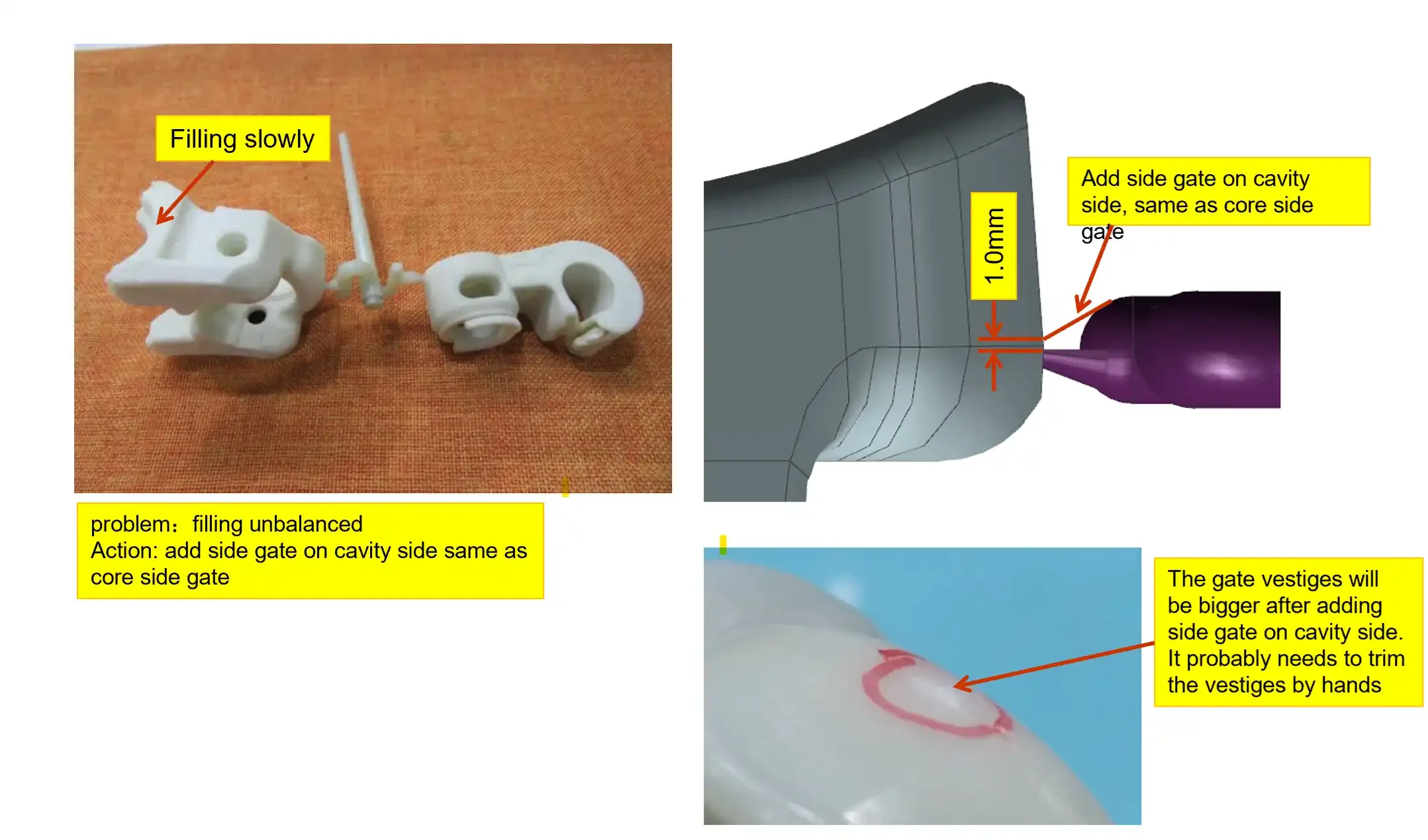

Design for Manufacturability

Why It Matters

A thorough design for manufacturability review comes with all projects ensures that the parts can be molded efficiently and at a low cost, minimizes costly revisions and delays during production.

How We Succeed

Implement a DFM checklist to ensure all parts meet manufacturability standards before moving forward with mold design.

Suggest modications to simplify part geometry, reduce cycle time, or enhance material flow, reducing overall time and cost.

Focus on standardization in part designs, which makes them easier and cheaper to manufacture.

Support And Maintenance

Why It Matters

Molds used in low-volume production still require maintenance, modifications, and repairs. Providing ongoing support and maintenance ensures the longevity of the mold and helps avoid costly downtime during production.

How We Succeed

Provide lifetime mold maintenance to ensure tools remain in optimal condition, giving customers peace of mind.

Offer modications for molds that require adjustments after the initial production run, whether due to part design changes or cycle time reduction.

Quality Control

Why It Matters

Even though low-volume production requires fewer units, the quality of each part remains critical. Customers expect high-quality, precise parts even at small quantities. Any defects or inconsistencies can erode customer trust and satisfaction.

How We Succeed

Implement rigorous quality control (QC) processes to ensure that all parts meet design specications and tolerances.

Conduct regular inspections and provide test samples to verify part quality before full production begins.

Offer documentation such as inspection reports or first article inspection (FAI) documentation to assure project owners that parts meet the expectations.