Get an Answer Today

Click an option to get connected to our U.S. engineering team:

You’ll be connected with one our

engineers in Lakeland, Florida.

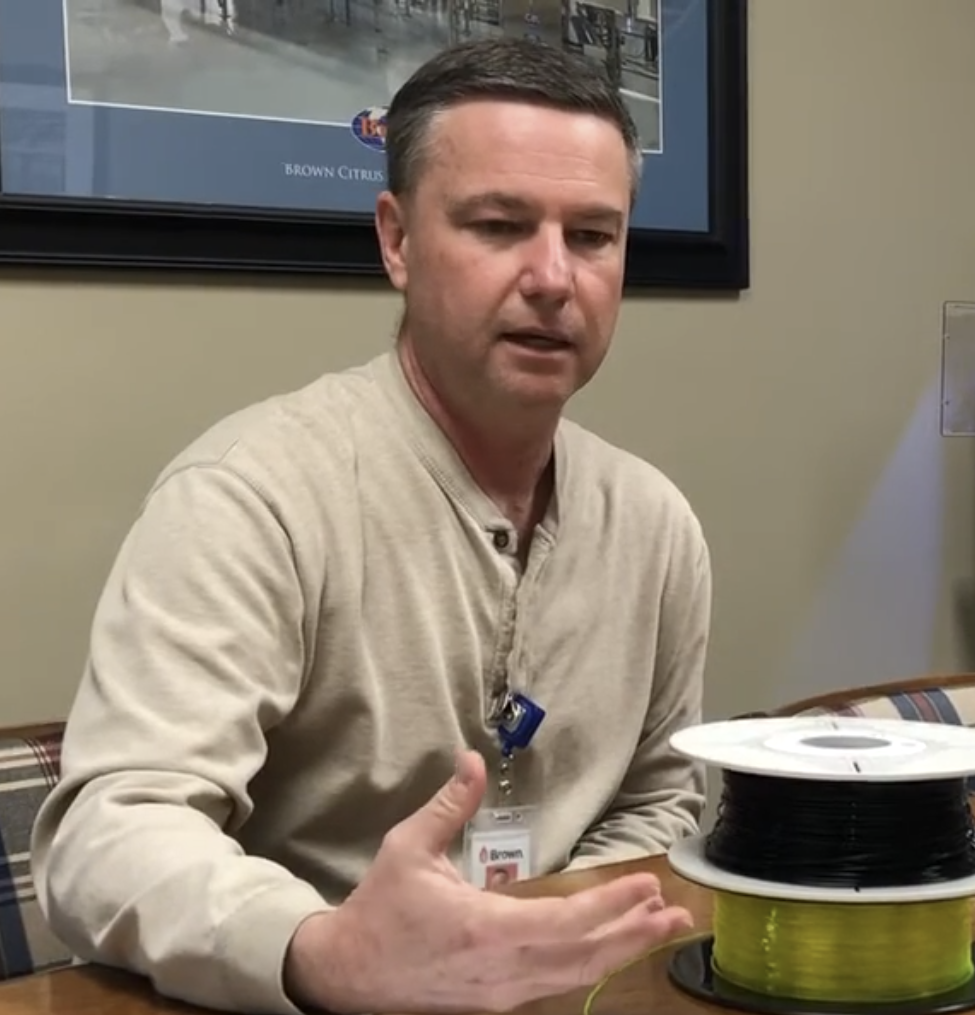

Manufacturing Engineer

CAD Design

Engineer

Direct Line:

Talk through your part, materials, and goals so we can outline realistic costs and lead times.

Call a CAD Design Engineer

Discuss your idea or existing part and learn what’s needed to create a proper CAD model.

Call a Manufacturing Engineer

Explore Quote Offers

Select an option to submit more detailed information on a current offer:

Start the design process of creating or reverse engineering your part/product.

Manufacturing Offer Inquiry

Design Offer Inquiry

Upload a design you already have to get details about cost and timeline.

Schedule Time on Teams

You’ll be connected with one our

engineers in Lakeland, Florida.

Manufacturing Engineer

Mechanical Design

Engineer

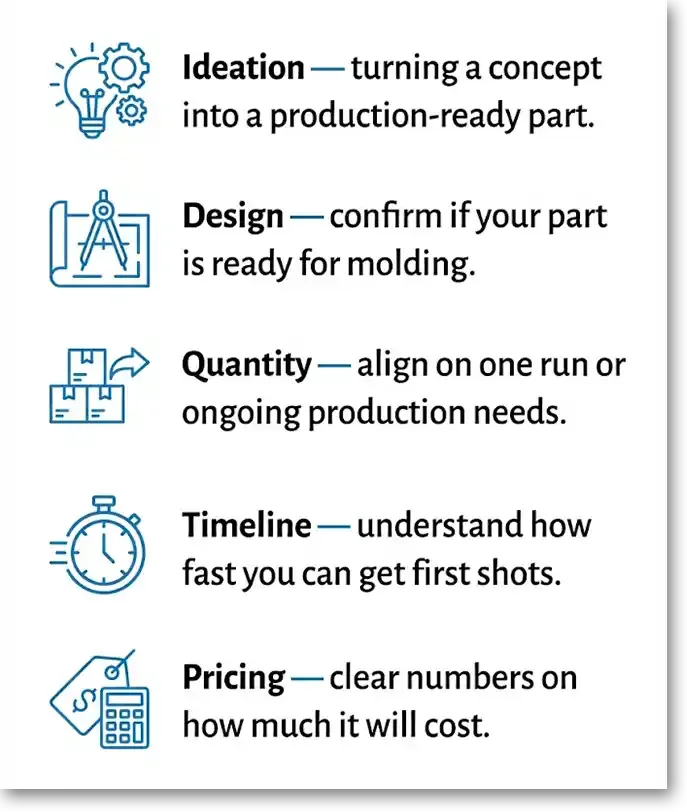

Design to Production: 6 Steps

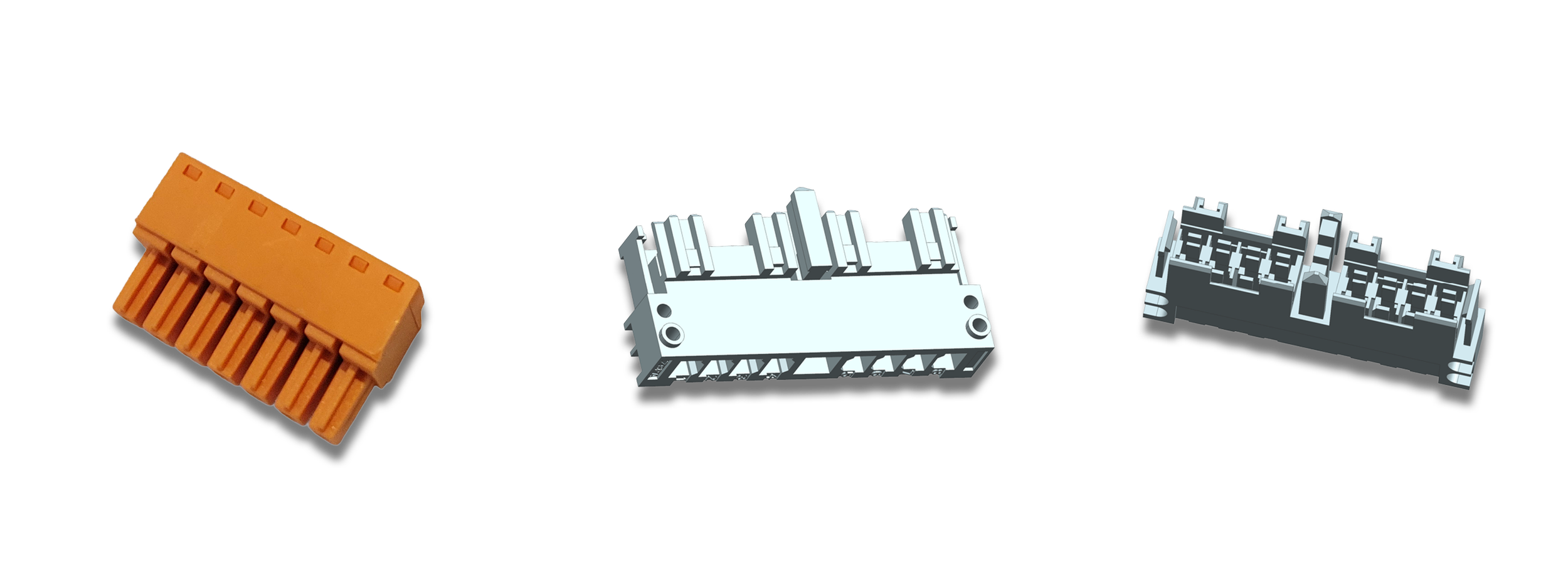

Send CAD File

Upload your CAD File for Review

No guesswork - we'll review your design and provide a transparent quote before moving forward.

Design Review

Determine the Molding Strategy

We translate needs for your product such as strength and heat resistance into a design specification and plan.

Prototyping & Down Payment

Start Finalizing the Model

With a 50% down payment, we can begin prototyping for your iteration process and move toward samples.

Sample Parts

Ensure Final Fit & Finish

Sample parts give you the chance to see the final product before scaling up your production.

Full Payment

Clear for Full Production

Finalizing payment gives the clear for full production where you start taking delivery in volume.

Ongoing Manufacturing

Scale Up or Down Production

Our manufacturing process allows you to scale production for agility - whether it’s 1 part or 10,000.

Payment Terms

All projects require 50% down to begin, balance due net 10 from T1 approval. Full part balance delivery occurs after full payment.

Shipping Terms

Shipping fees are included in the overall price. China sourced parts are shipped AIR and domestic sourced parts are shipped GROUND.

CAD and Drawing Requirements

3D CAD files are required for mold construction- however, we offer reverse engineering services for existing parts.

Contact Us Directly

Phone

Visit Us In-Person

502 East Main Street

Lakeland Florida, 33809

We are always open to working with local businesses whenever possible.

Give us a call to schedule an in-person appointment or meeting.