Your partner in reverse engineering, injection molding, and assembly - chosen by:

Where Ideas Take Shape, One Part at a Time

Startups

|

Entrepeneurs

|

Innovators

|

Refurbishers

|

Retrofitters

|

Engineers

|

Marketers

|

Startups | Entrepeneurs | Innovators | Refurbishers | Retrofitters | Engineers | Marketers |

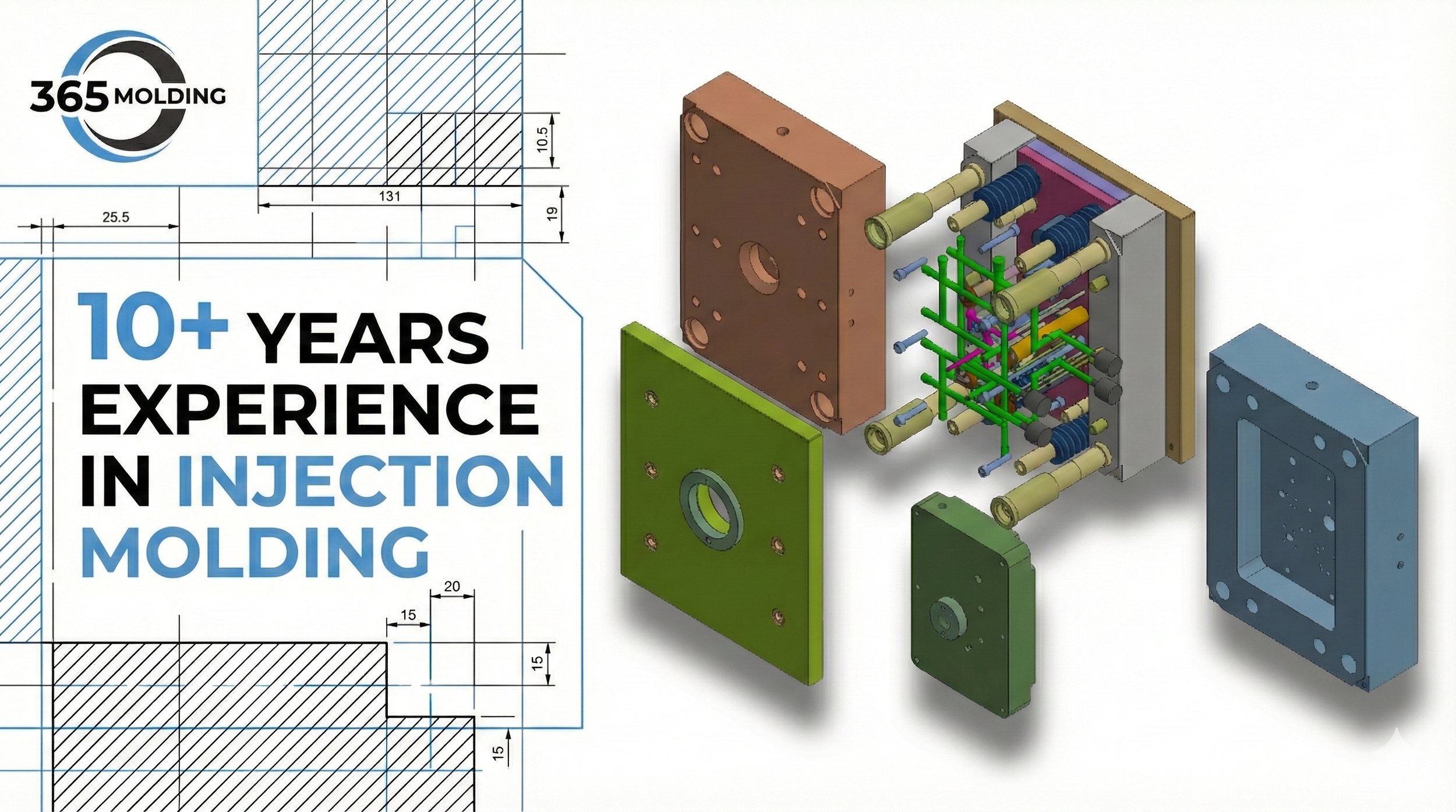

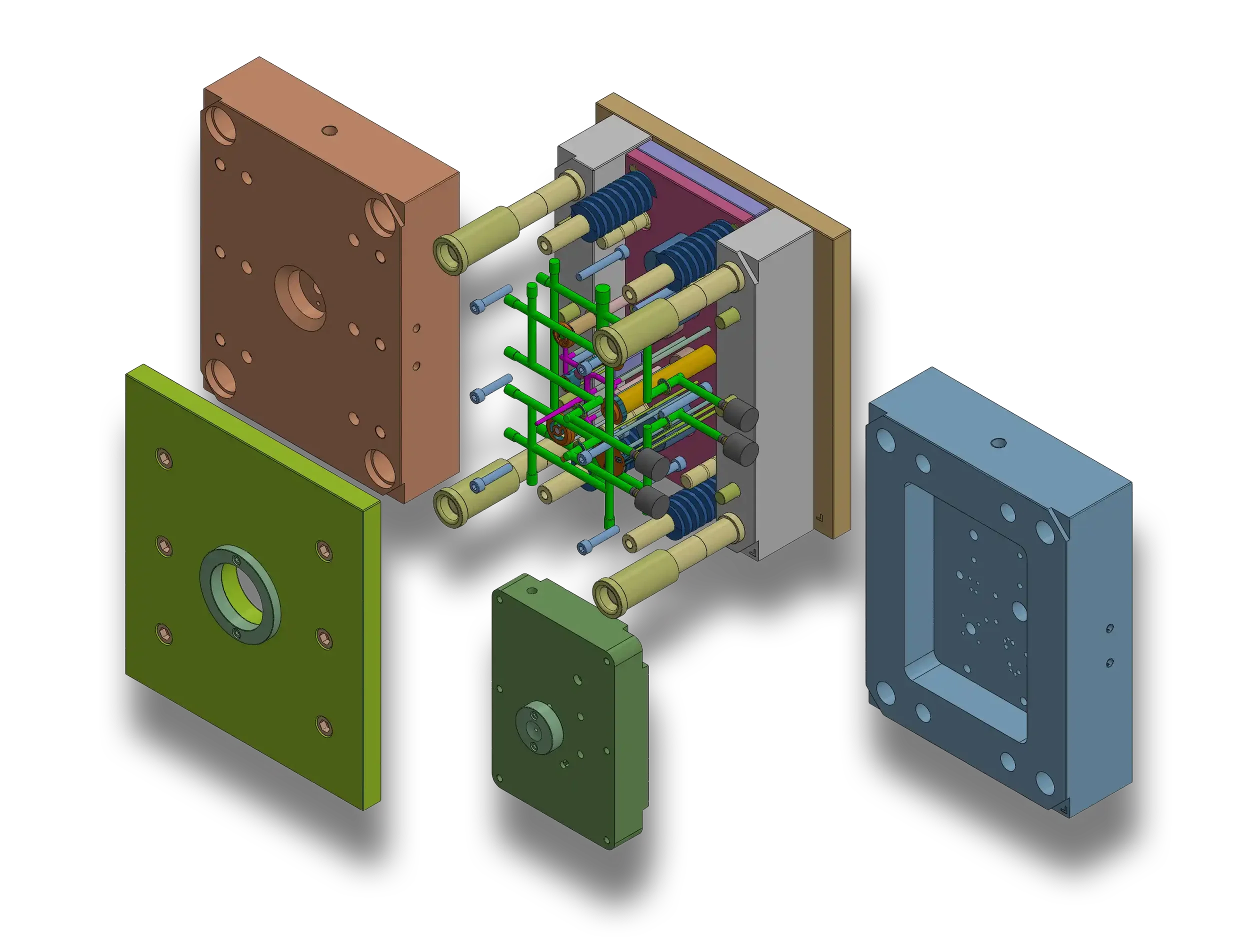

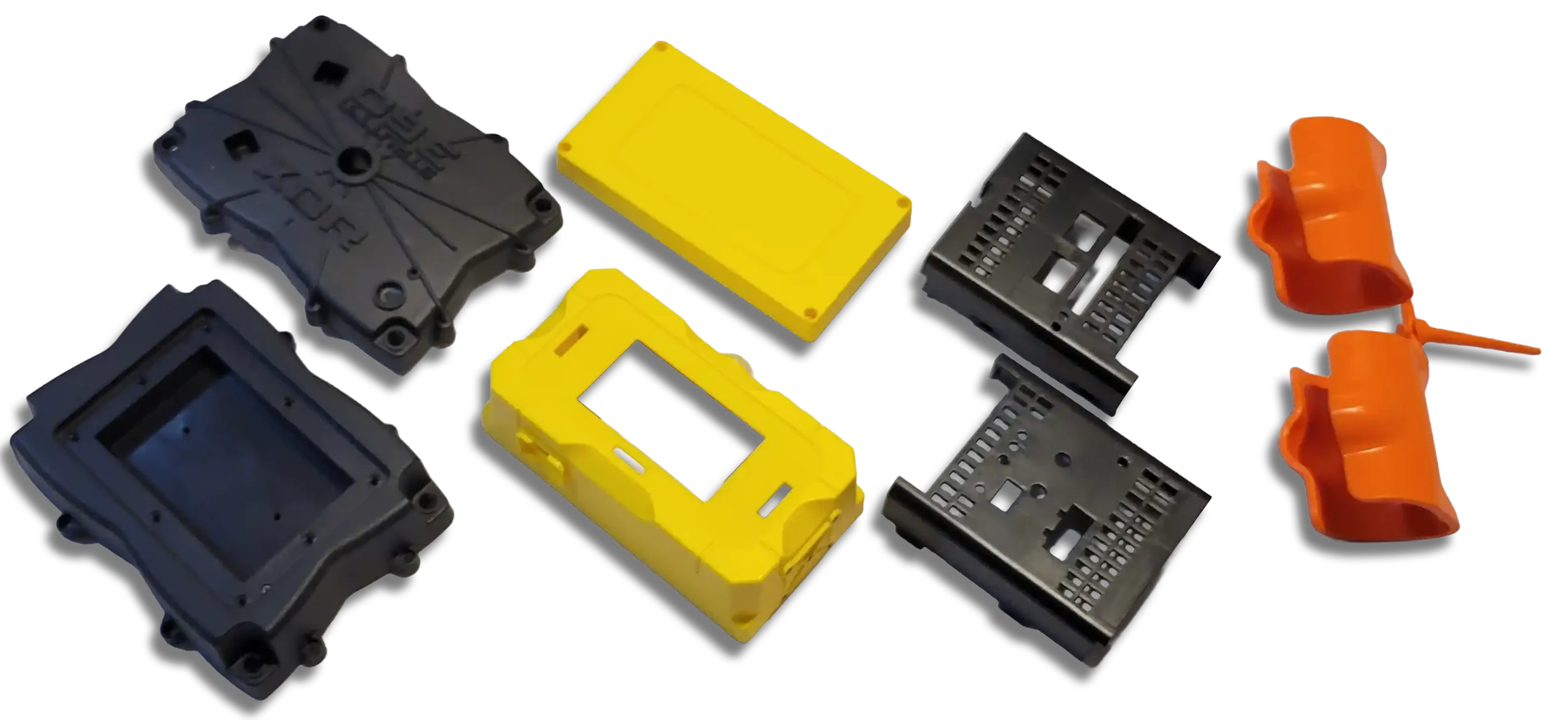

Wide Manufacturing Capabilities - Build Simple or Advanced Parts

Thermoplastic Materials

Insert Molding

Overmolding

Threaded Inserts

Pantone & RAL Colors

Secondary Operations

Rapid 3D Print Prototyping

Robust Design Capabilities - Design New or Obsolete Parts

Design New Parts & Products

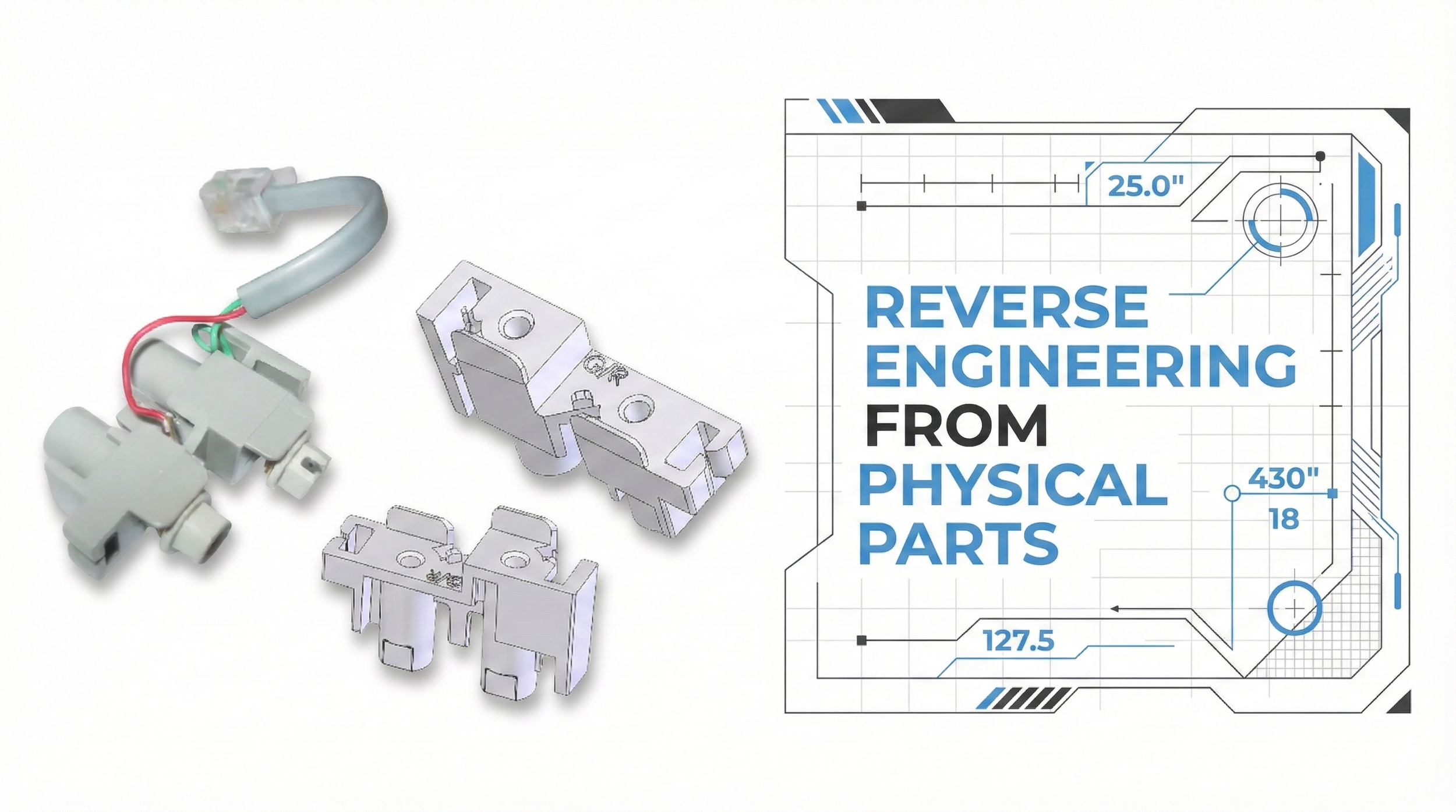

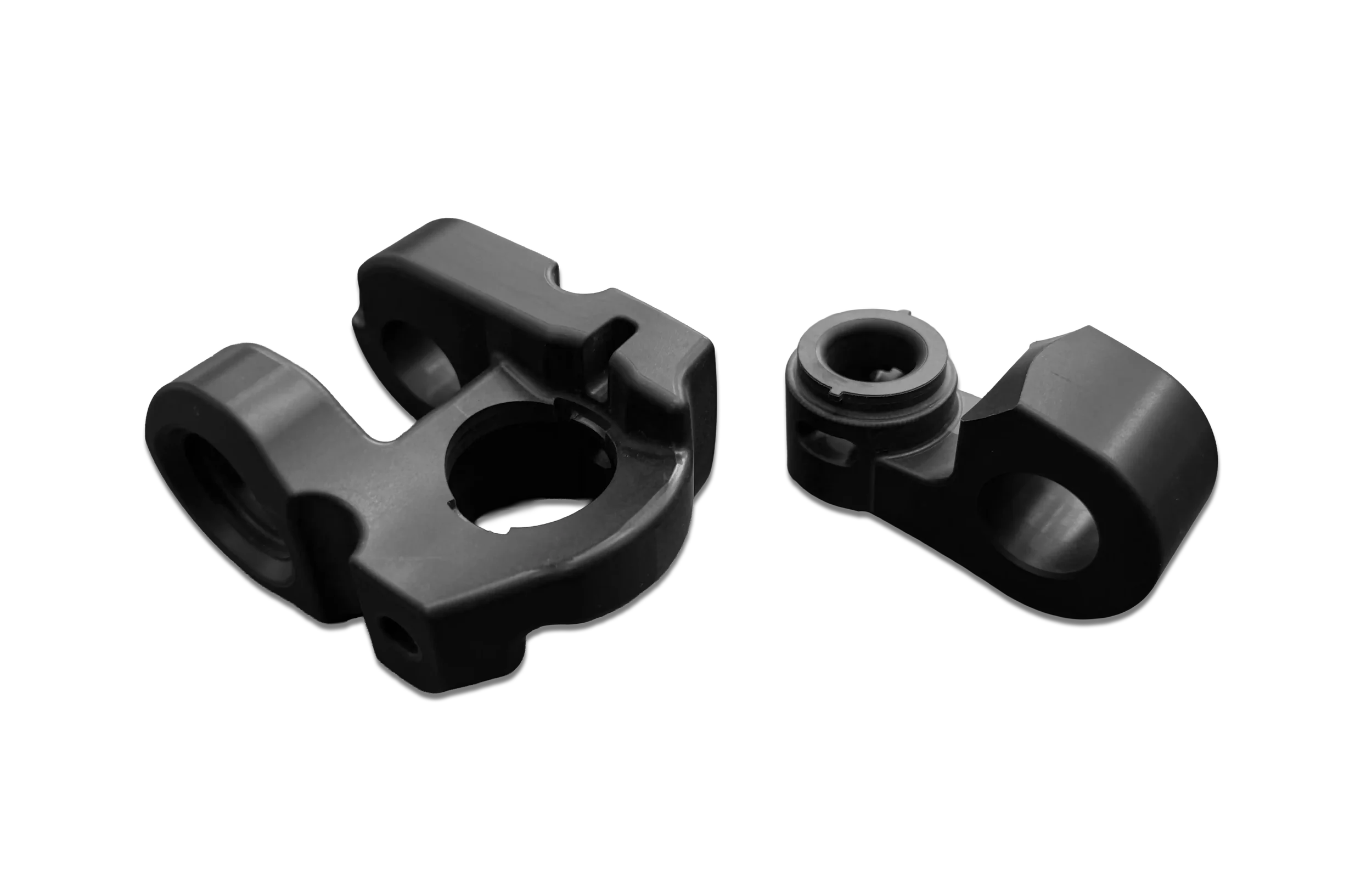

Reverse Engineer Existing Parts

Improve Legacy or Obsolete Parts

Adapt Designs for New Applications

Serving a Variety Of Companies And Markets

Consumer Products

Electronics

Industrial Hardware

Construction

Sporting Goods

Plumbing And Air Conditioning

More Processes Compared to On-Demand Services

The design and manufacturing you need - with the program management to make your project successful.

Compliant Manufacturing: Offered

Access to a provider network to create parts in compliance with ISO 9001.

Project Management: Offered

Guidance through every stage ensures the project stays on track and on time.

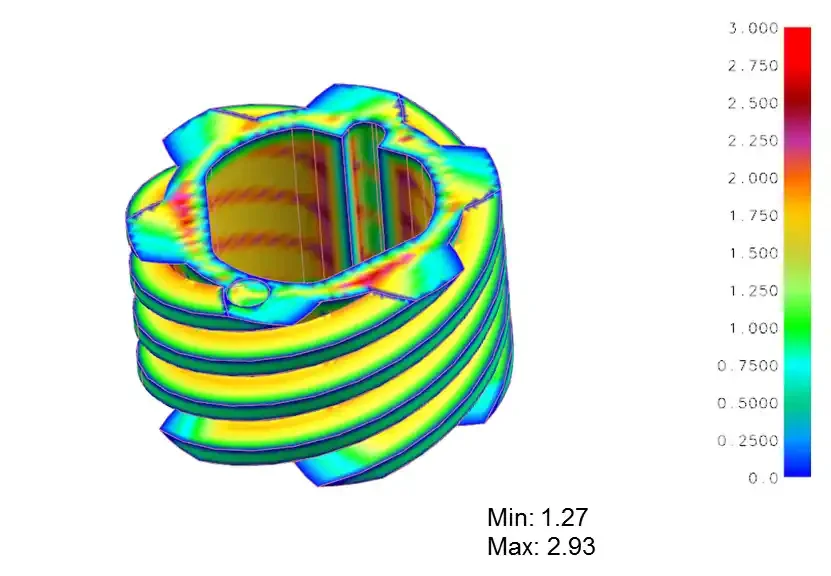

Engineering Analysis: Offered

Design analysis helps identify costly mistakes and blockers pre-production.

Production Management: Offered

Management of cost and timing for ongoing part production and delivery.

VS

Compliant Manufacturing: Offered

Access to a provider network to create parts in compliance with ISO 9001.

~$1075*

Project Management: Additional

Must supply an internal staff member to act as the project champion.

~$1000*

Engineering Analysis: Additional

Must supply your own engineer or pay a 3rd-party to review your design.

~$1260*

Production Management: Additional

Must supply internal staff to handle ordering, scheduling, and deliveries.

*Estimates based on 2025 U.S. rates, using average labor rates and time estimates for a single-cavity injection-molded part.

Explore 365 Molding

Processes

See how we transform CAD files into parts with fully managed production.

Capabilities

Understand the different methods of mold & design available.

Case Studies

See examples of previous projects to guage your current needs and budget.

Our Services

Injection Molding

365 Molding provides low-cost, high-quality injection molds.

Short runs as small as 100 pieces

Annual production of 50,000+

Virtually any thermoplastic material

Match any Pantone or RAL color.

Design Review

All projects are reviewed for manufacturability.

Confirm proper gating

Mold flow

Tool construction

3d Printing And Prototypes

When Possible We Provide 3d Printed Verification Models For Our Clients To Ensure Proper Fit, Form, And Function Before Mold Construction Begins.